Plastic Injection Molding: Revolutionizing Product Manufacturing

Introduction

Plastic injection molding has dramatically transformed how products are designed and manufactured in today’s industrial landscape. It is a highly efficient and cost-effective method for producing plastic parts in large volumes. Whether you’re holding a toothbrush, a car dashboard, or a computer mouse, there’s a high chance it was manufactured through plastic injection molding.

This article explores the fundamentals, benefits, applications, and evolving innovations in offering insight into why it remains a cornerstone of modern manufacturing.

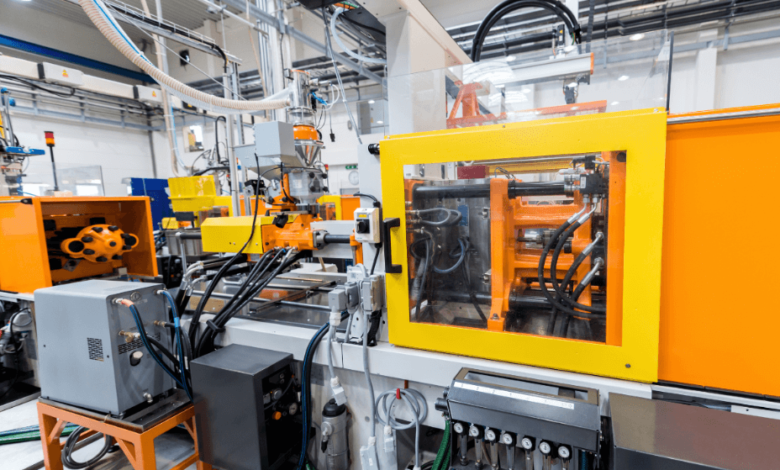

What is Plastic Injection Molding?

Once the plastic cools and hardens, the mold opens to eject the finished product. The entire process is automated and allows for mass production of identical parts with high precision.

Basic Steps Involved:

- Mold Clamping – The mold is securely closed using hydraulic force.

- Cooling – The injected plastic cools and solidifies into the shape of the mold.

- Part Ejection – The mold opens and ejector pins push out the molded component.

The entire cycle can take just a few seconds to complete, making it ideal for producing thousands or even millions of parts quickly and consistently.

Materials Used in Plastic Injection Molding

A wide variety of plastics can be used in this process depending on the product’s purpose, required strength, flexibility, and environmental resistance. Some of the most common plastics include:

- Polypropylene (PP): Lightweight, durable, and suitable for packaging.

- Acrylonitrile Butadiene Styrene (ABS): Tough and impact-resistant, often used in consumer electronics.

- Nylon (PA): Used for gears, bearings, and mechanical components due to its wear resistance.

- Polyethylene (PE): Commonly used in containers and bottles.

Custom compounds and fillers can also be added to enhance specific material properties like fire resistance, UV stability, or conductivity.

See also: Leveraging Technology to Boost Business Efficiency

Benefits of Plastic Injection Molding

Plastic injection molding offers numerous advantages, especially when high production volumes and precise component specifications are needed. Some major benefits include:

1. High Efficiency

Once the molds are made, the process is incredibly fast. With cycle times ranging from a few seconds to under a minute, manufacturers can produce thousands of units daily.

2. Cost-Effectiveness

Although mold development may involve high initial investment, the low per-unit cost during mass production leads to significant long-term savings.

3. Superior Consistency

Injection molding guarantees uniformity and accuracy from the first part to the millionth. This level of consistency is vital in sectors like automotive and medical equipment.

Applications of Plastic Injection Molding

Plastic injection molding is used across various sectors thanks to its adaptability and high output. Let’s explore some of the major areas:

Automotive Industry

These parts are lightweight, which improves fuel efficiency.

Consumer Goods

From kitchenware and storage containers to toys and cosmetic packaging, plastic injection molding is essential in producing durable and aesthetically appealing items.

Medical Devices

Components such as syringes, surgical instruments, housings for medical monitors, and diagnostic tools are manufactured using medical-grade plastics.

Customization in Plastic Injection Molding

One of the most significant advantages of this technology is the wide scope for customization. Manufacturers can choose:

- Mold Configuration: Single or multi-cavity molds depending on production needs.

- Surface Finishing: Glossy, matte, textured, or engraved finishes.

- Color Options: Plastic resins can be dyed or painted post-production.

- Special Features: Inserts, overmolding, and multi-material designs for unique applications.

This flexibility enables brands to develop unique and functional products tailored to specific market requirements.

Challenges in Plastic Injection Molding

- High Upfront Tooling Cost: Designing and manufacturing a custom mold can be expensive and time-consuming.

- Design Limitations: While complex shapes are possible, undercuts or overly thick sections can be difficult to mold.

- Lead Time for Tooling: Initial setup may take weeks, especially for intricate designs or prototypes.

- Material Compatibility: Some plastics may degrade if not processed correctly, requiring strict control over temperature and pressure.

Technological Advancements

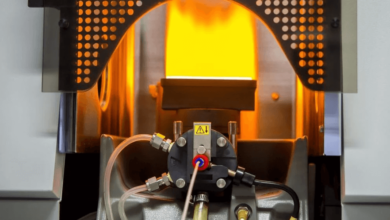

Micro Molding

Used in industries like electronics and medical, micro molding allows for the production of ultra-small components with extremely tight tolerances.

Biodegradable Plastics

With rising environmental concerns, manufacturers are increasingly adopting biodegradable and bio-based plastics to reduce their carbon footprint.

3D Printed Molds

3D printing technology allows for rapid prototyping and short-run molds at a fraction of the cost and time of traditional steel tooling.

Choosing a Reliable Molding Partner

Selecting the right service provider is essential for a successful plastic injection molding project. Consider the following:

- Experience and Portfolio: Proven history in your industry or product type.

- Quality Certifications: Look for ISO or industry-specific certifications.

- In-House Capabilities: Design, tooling, prototyping, and molding under one roof.

- Material Expertise: Familiarity with a wide range of polymers and additives.

- Scalability: Ability to handle small batches as well as high-volume production.

A trusted partner helps reduce production risks and ensures on-time delivery with consistent quality.

Conclusion

Plastic injection molding remains a key pillar of industrial manufacturing, enabling mass production of complex and durable components at scale. With its unmatched efficiency, design flexibility, and repeatability, it serves as an essential process across diverse sectors—from medical and automotive to consumer electronics and packaging.

As innovation continues to evolve the field, manufacturers who leverage advanced plastic injection molding technologies stand to gain in speed, sustainability, and competitiveness. Whether you’re developing a high-tech gadget or a household item, the possibilities offered by this manufacturing technique are virtually limitless.